Highlights

Acrylic UV Material Case Study

Working in collaboration with the OEM’s engineering teams from the earliest R&D stage, we were able to design and develop a part manufacturing process that met the high-quality specifications required to successfully produce lens components for a cancer screening device. In addition, our end-to-end capabilities offered solutions that halved their final production costs, allowing for higher, faster production volumes.

Industry: Healthcare

Solution:Developing and manufacturing integral new parts for cutting-edge medical equipment

Products: Acrylic UV material

Results:A more cost-effective production process that ensured part quality throughout

Challenge

Improving part design and efficiencies to ensure consistent production quality

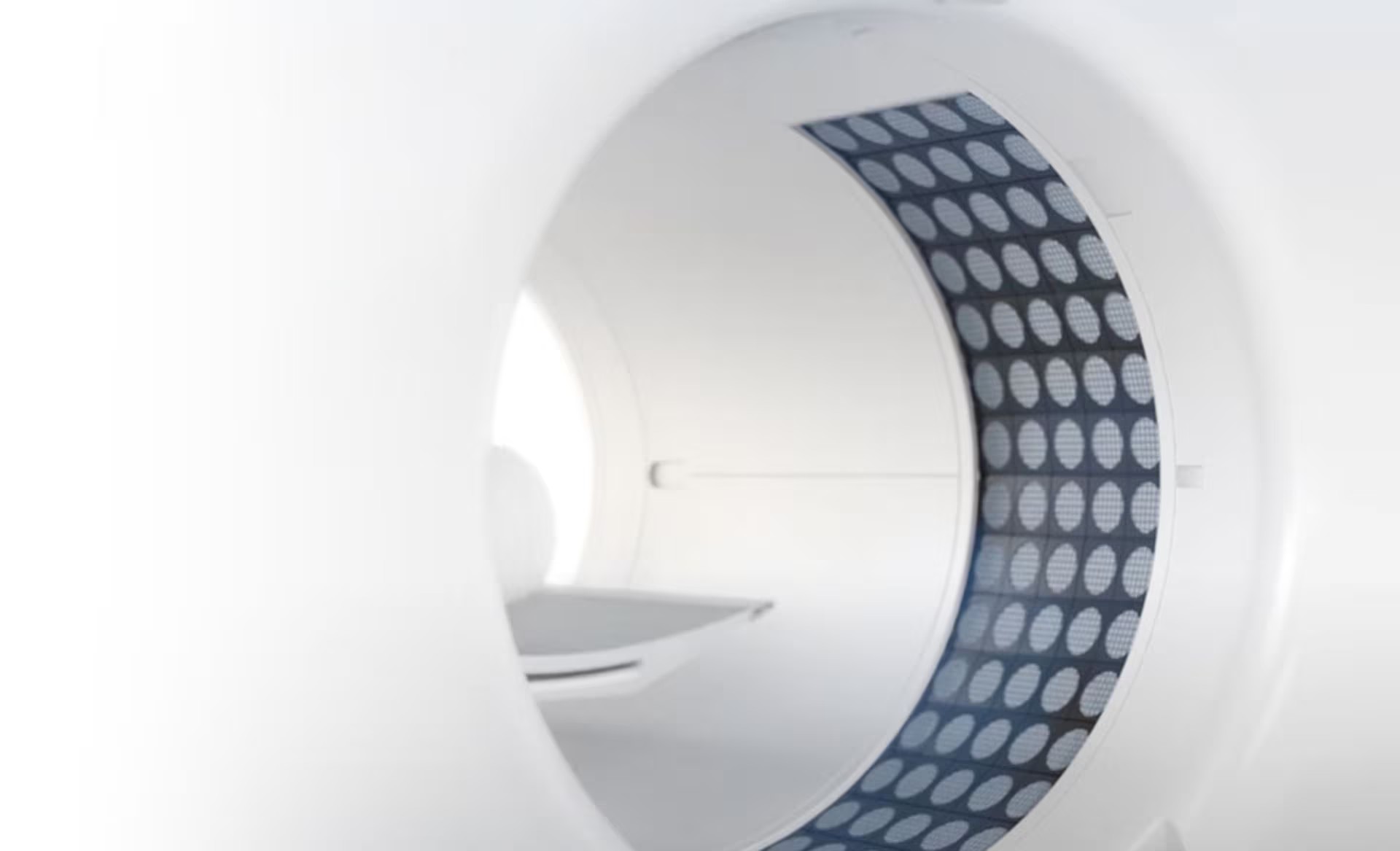

While in the process of designing a new high-tech cancer screening device that required a complex light guide system, a well-known Healthcare OEM needed help getting their ideas into production.

Having already specified the material they required, we partnered with them to help improve their design and solve their manufacturing challenges, which required a combination of cost savings without compromising on part quality.

Solution

From prototype to production

Our expert part design and production support teams initially developed a unique CNC machined acrylic lens component. But the OEM needed a more competitive solution that allowed for faster turn-around times and increased production volume at a lower cost.

Working in collaboration with our customer’s engineering teams, we were able to test a number of production options, adjusting our designs and methodologies to meet the high specifications required for the final part. After extensive testing, we developed a unique injection molding technique that halved the production cost of each part.

Results

Maintaining part quality every step of the way

From perfecting the initial design, to trialling, testing and double-checking the final production processes, our expertise and cross-capabilities meant the OEM was able to ensure the very highest level of quality, while benefiting from the cost-savings of higher production volumes and clever manufacturing solutions.

High-spec medical grade materials

Engineering design support, assembly & testing

End-to-end solutions

Exceptional quality control

Lower overall production costs

Significant increase in production volumes

More Information on Mitsubishi Materials Sales

At Novaplas Precision, we specialize in the sales of high-quality Mitsubishi engineering plastics, offering a range of materials suitable for various industrial applications. We provide materials with superior quality, no porosity, and fast delivery times to meet your production needs.If you have any questions about Mitsubishi materials or would like to place an order, please don’t hesitate to contact us. We are here to assist you with your material requirements and ensure timely delivery.

Lucky: General Manager

+86 151 9032 3888 (WhatsApp available)

lucky@novaplas.cn