航空航天

了解我们如何帮助安全和安保工作面向未来。

From bioprocessing solutions, to short term body-contact materials, to long term implantable plastics — when you partner with Mitsubishi Chemical Group, you have access to the market's most comprehensive portfolio of thermoplastic shapes for a full range of healthcare applications.

Made from high-quality resins with an emphasis on traceability and pre-assessment testing, our products provide OEMs in diverse healthcare sectors with both the material properties and testing support they need. We pre-assess both initial resins and semi-finished shapes for biocompatibility requirements, giving you a head start in material selection that can reduce costs and accelerate the process.

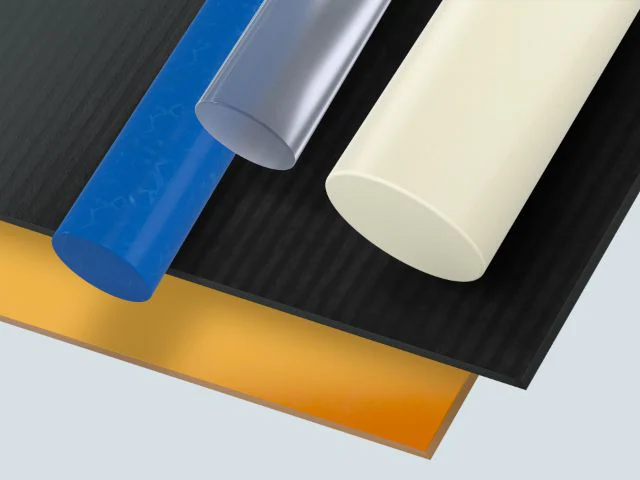

Pre-assessed for biocompatibility on both resin and stock shape, the Life Science Grade (LSG) portfolio includes a comprehensive range of high-performance plastics that are excellent candidates for use in bioprocessing and short-term body contact applications.

Encompassing PEEK, PPSU, PEI, PSU, polycarbonate, polypropylene, and high density polyethylene, the LSG semifinished shapes from Mitsubishi Chemical Group meet the most demanding requirements for performance.

Explore MediTECH — the market's largest portfolio of pre-assessed, implantable PEEK and UHMW-PE stock shapes. With complete traceability from resin to semi-finished shape, Chirulen™, Extrulen™, and Zeniva™ materials are excellent candidates for the manufacture of long-term implants in the fields of orthopedics and dentistry.

Chirulen™ and Extrulen™ can be crosslinked to reduce wear and extend their lifetime. Antioxidants such as vitamin E can also be blended into the resin prior to conversion in order to prevent oxidation and material degradation of the semi-finished stock shape.

The new EU MDR involves major changes that will impact the way that medical device manufacturers approach the material selection process.

In this webinar, held in November 2023, three experts walk you through the background of the new MDR, its implications for the polymeric material sourcing process, and measures that device manufacturers can take to prepare.

The human body is complex, and so is navigating the approval and regulatory process for bringing new medical devices to market.

We help you evaluate material data (including our biocompatibility pre-assessments) to provide you with a robust and tailored selection of candidate materials for your specific healthcare application and regulatory requirements.

The production and machining of MediTECH implantable and Life Science Grade shapes is undertaken within ISO 13485 certified quality management systems.

Lucky: General Manager

+86 151 9032 3888 (WhatsApp available)

lucky@novaplas.cn

了解我们如何帮助安全和安保工作面向未来。

了解我们如何提高可持续性、加工安全性和产量。

了解我们如何让更多的可持续能源选择成为可能。

了解我们如何在最具挑战性的高科技环境中实现更精确的性能。

了解我们如何帮助人类进步。

了解我们如何帮助汽车行业加快发展。

通过我们的热塑性衬里材料组合,我们能够更安全、更快速、更轻松、更高效地处理散装货物。

了解我们如何帮助化工行业生产、存储和处理产品。

了解我们如何为多种重工业应用提供交钥匙解决方案。

先进的工程材料可以帮助您改变游戏规则。

了解我们如何帮助为每个人构建更美好的环境。

了解我们如何让更顺畅的旅程成为可能。