Aérospatiale

Découvrez comment nous contribuons à préparer l'avenir en matière de sûreté et de sécurité.

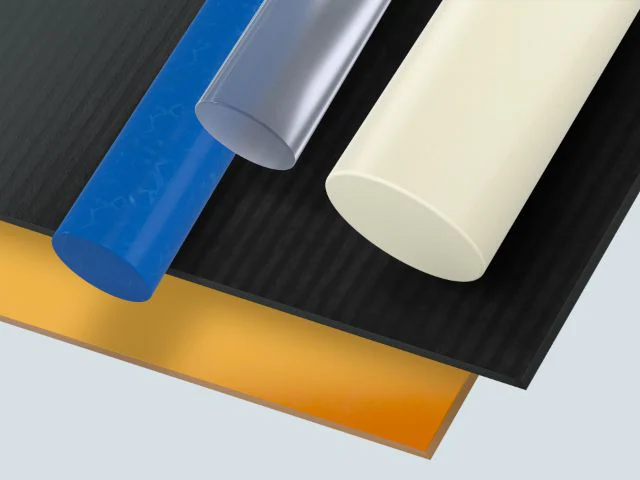

From bioprocessing solutions, to short term body-contact materials, to long term implantable plastics — when you partner with Mitsubishi Chemical Group, you have access to the market's most comprehensive portfolio of thermoplastic shapes for a full range of healthcare applications.

Made from high-quality resins with an emphasis on traceability and pre-assessment testing, our products provide OEMs in diverse healthcare sectors with both the material properties and testing support they need. We pre-assess both initial resins and semi-finished shapes for biocompatibility requirements, giving you a head start in material selection that can reduce costs and accelerate the process.

Pre-assessed for biocompatibility on both resin and stock shape, the Life Science Grade (LSG) portfolio includes a comprehensive range of high-performance plastics that are excellent candidates for use in bioprocessing and short-term body contact applications.

Encompassing PEEK, PPSU, PEI, PSU, polycarbonate, polypropylene, and high density polyethylene, the LSG semifinished shapes from Mitsubishi Chemical Group meet the most demanding requirements for performance.

Explore MediTECH — the market's largest portfolio of pre-assessed, implantable PEEK and UHMW-PE stock shapes. With complete traceability from resin to semi-finished shape, Chirulen™, Extrulen™, and Zeniva™ materials are excellent candidates for the manufacture of long-term implants in the fields of orthopedics and dentistry.

Chirulen™ and Extrulen™ can be crosslinked to reduce wear and extend their lifetime. Antioxidants such as vitamin E can also be blended into the resin prior to conversion in order to prevent oxidation and material degradation of the semi-finished stock shape.

The new EU MDR involves major changes that will impact the way that medical device manufacturers approach the material selection process.

In this webinar, held in November 2023, three experts walk you through the background of the new MDR, its implications for the polymeric material sourcing process, and measures that device manufacturers can take to prepare.

The human body is complex, and so is navigating the approval and regulatory process for bringing new medical devices to market.

We help you evaluate material data (including our biocompatibility pre-assessments) to provide you with a robust and tailored selection of candidate materials for your specific healthcare application and regulatory requirements.

The production and machining of MediTECH implantable and Life Science Grade shapes is undertaken within ISO 13485 certified quality management systems.

Chanceux : Directeur général

+86 151 9032 3888 (WhatsApp disponible)

lucky@novaplas.cn

Découvrez comment nous contribuons à préparer l'avenir en matière de sûreté et de sécurité.

Découvrez comment nous améliorons la durabilité, la sécurité des processus et le rendement.

Découvrez comment nous rendons possibles des options énergétiques plus durables.

Découvrez comment nous rendons possibles des performances plus précises dans les environnements de haute technologie les plus difficiles.

Découvrez comment nous aidons l'humanité à progresser.

Découvrez comment nous aidons l'industrie automobile à progresser plus rapidement.

Notre portefeuille de matériaux de revêtement thermoplastique permet une manutention plus sûre, plus rapide, plus facile et plus efficace des marchandises en vrac.

Découvrez comment nous aidons l'industrie chimique à produire, stocker et manipuler ses produits.

Découvrez comment nous fournissons des solutions clés en main pour de multiples applications industrielles lourdes.

Les matériaux techniques avancés peuvent vous aider à changer la donne.

Découvrez comment nous contribuons à la construction d'un meilleur environnement pour tous.

Découvrez comment nous rendons possibles des voyages plus fluides.