Duratron™ U1000 PEI Case Study

Unser umfassendes Portfolio an fortschrittlichen Werkstoffen bot zwar eine zuverlässigere und reinere Polymerlösung, aber dank unserer kooperativen Unternehmenskultur und unseres innovativen Ansatzes für Partnerschaften waren wir in der Lage, das außergewöhnlich hohe Volumen an benötigten Materialien und Teilen in einem sehr kurzen Zeitrahmen zu liefern.

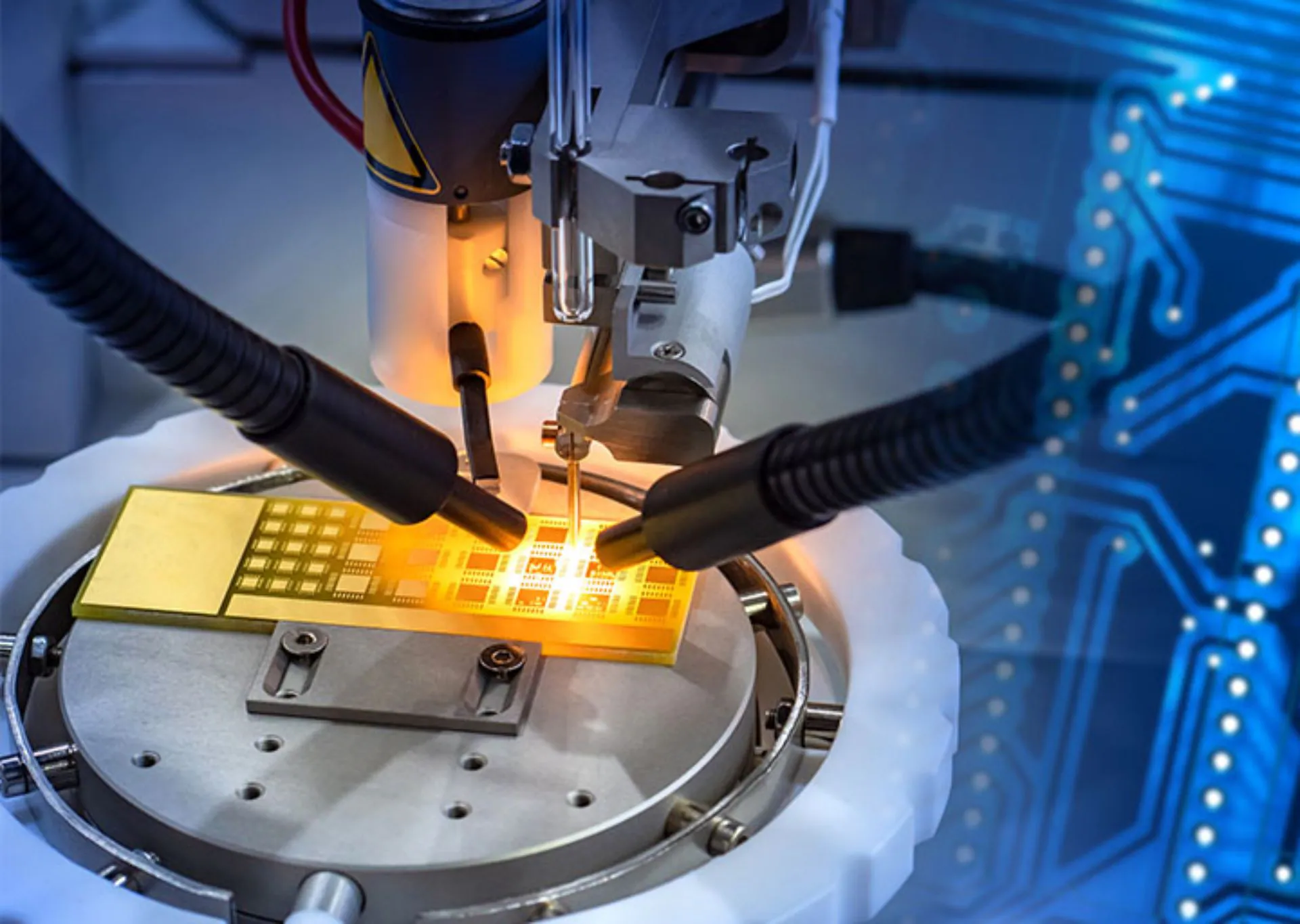

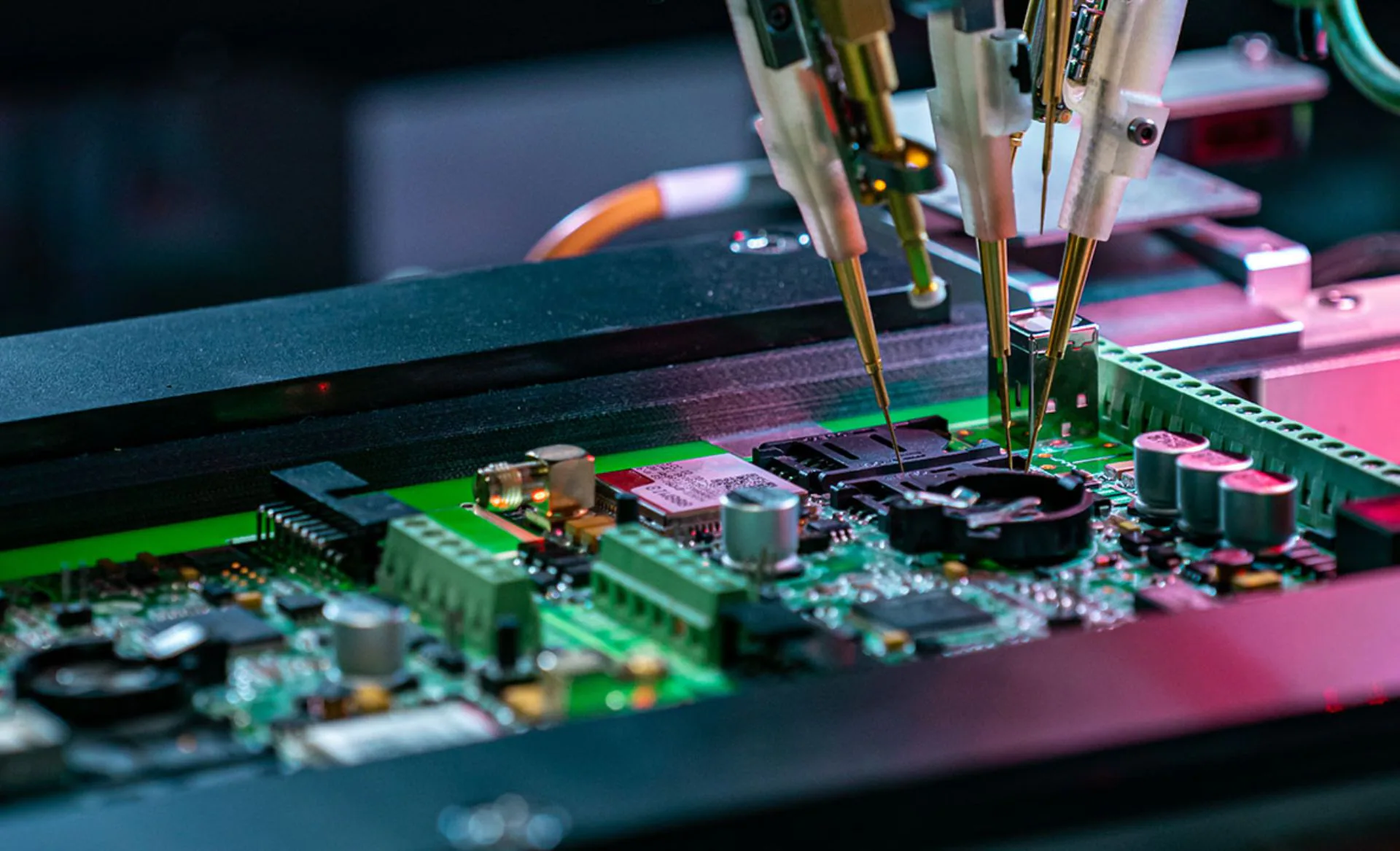

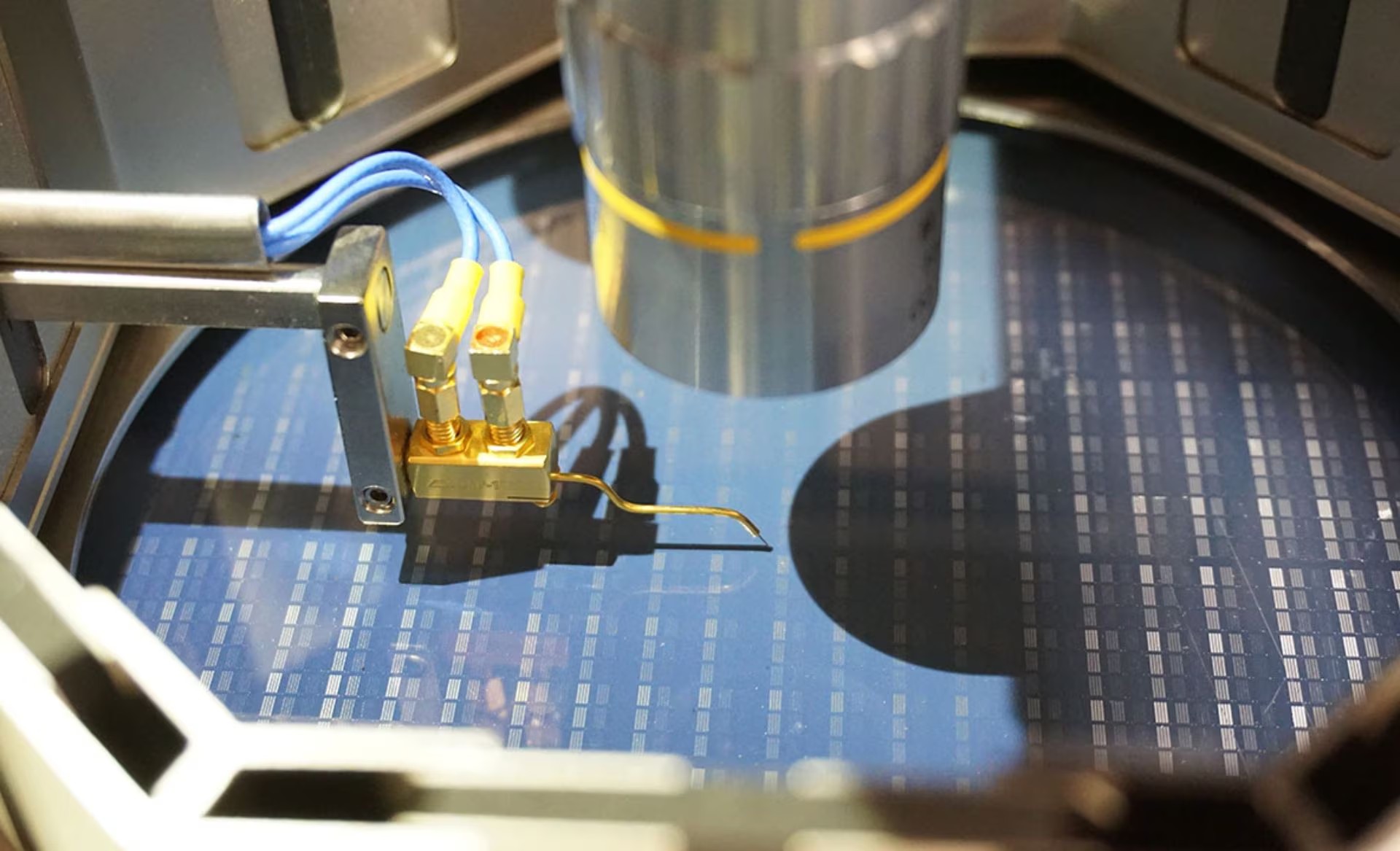

Industrie: Halbleiter & Elektronik, Chipherstellung

Lösung: Nachrüstung eines gesamten globalen Betriebs mit sichereren, zuverlässigeren Umlenkblechen aus hochfestem Hochtemperatur-Polymer

Produkte: Duratron™ U1000 PEI, an amorphous polymer

Ergebnisse: Sicherere, kostengünstigere Teile und eine globale Umrüstung in Rekordzeit und in Rekordmengen

Herausforderung

Einhaltung des Kundenvolumens und der Zeitvorgaben ohne Qualitätseinbußen

Um auf die zunehmenden Prozessänderungen zu reagieren, die höhere Temperaturen oder fortschrittliche Materialien erfordern, musste unser Kunde die in seinen Halbleiterfertigungsanlagen verwendeten Materialien schnell durch einen zuverlässigeren, hochtemperaturbeständigen Kunststoff für seinen gesamten weltweiten Betrieb ersetzen.

Die in der Halbleiterfertigung verwendeten Ablenkbleche sind in den Maschinen ständig extrem hohen Temperaturen ausgesetzt und können sich entzünden, wenn sie zu heiß werden. Jeder Rauch würde die Reinraumumgebung verunreinigen und zu einem kostspieligen Produktionsstopp führen. Daher müssen die verwendeten Materialien sowohl gegen hohe Temperaturen als auch gegen Feuer beständig sein.

Der Erstausrüster musste in jeder aktiven Fertigungskammer an jedem seiner weltweiten Produktionsstandorte mehrere Prallplattenkomponenten nachrüsten.

Lösung

Ein skalierbarer und effizienterer Ansatz

Trotz nahezu unmöglicher Zeit- und Mengenvorgaben konnten wir eine einzige Lösung anbieten, die nicht nur die Materialanforderungen des OEMs erfüllte, sondern auch seinen sehr anspruchsvollen Lieferplan.

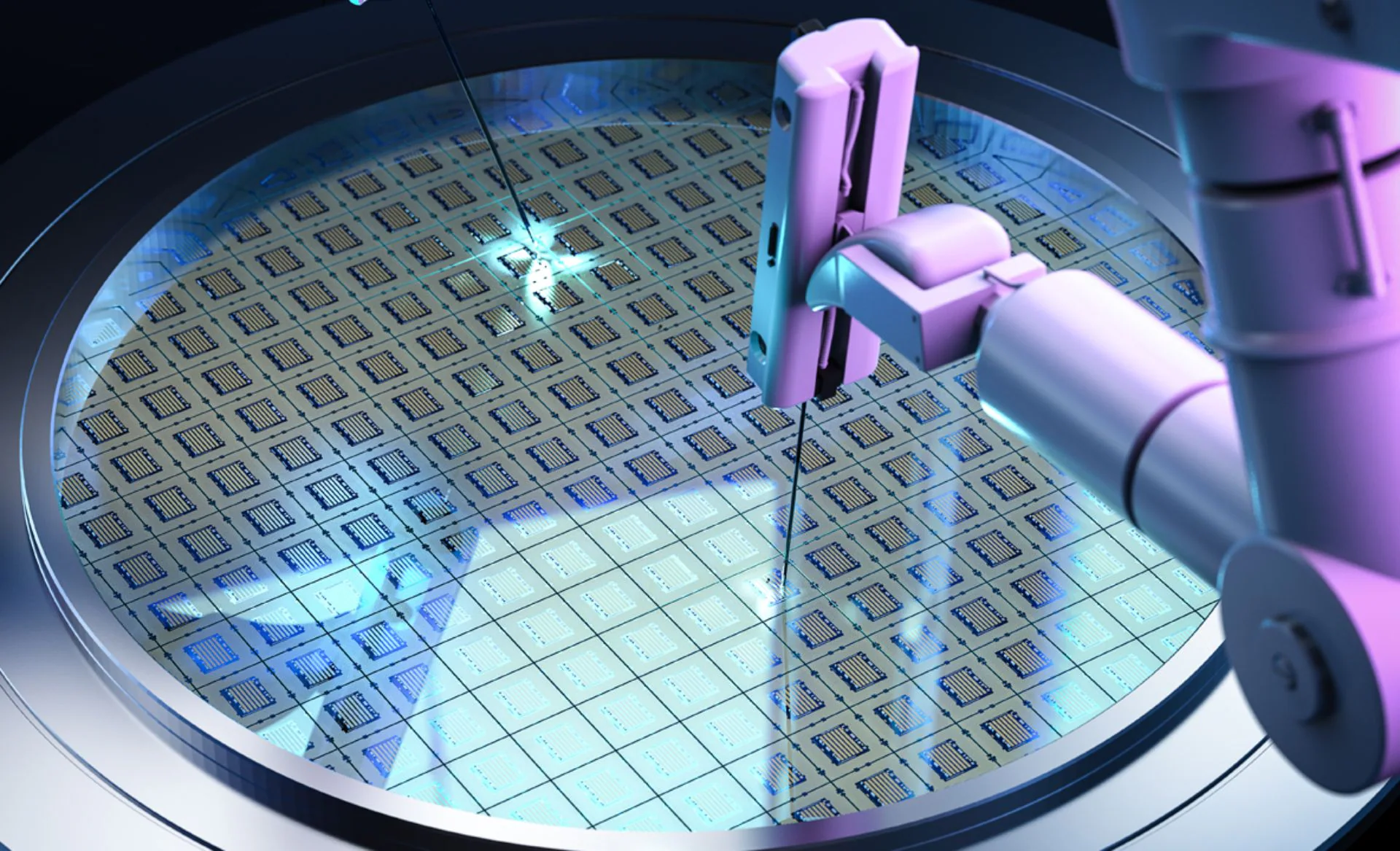

Dank unserer vertikal integrierten Struktur und unserer Fähigkeit, ein breites Spektrum an Produktionskapazitäten zu nutzen, waren wir in der Lage, die Extrusionspläne anzupassen und zusätzliche Ressourcen und mehrere Anlagen einzusetzen, um die erforderliche Menge an hochtemperaturbeständigen Ablenkblechen schneller und effizienter als unsere Wettbewerber zu produzieren.

Mithilfe einer Kombination innovativer Technologien konnten wir eine noch nie dagewesene Anzahl von Platten - Hunderte pro Woche - bearbeiten, um qualitativ hochwertige Ablenkbleche aus zuverlässigen und hochtemperaturbeständigen Kunststoffen herzustellen, die sowohl den Zeitplan als auch die Sicherheitsanforderungen unseres Kunden erfüllen.

Ergebnisse

Eine globale Umrüstung in Rekordzeit

With proven high strength and excellent flame and heat resistance, Duratron™ U1000 PEI solved our customer’s initial safety and contamination issues, enabling them to maintain their market-leading position. And, by leveraging our powerful network of capabilities and facilities, we helped the OEM move to more sustainable, cost-effective methods of production while simultaneously achieving a massive global retrofit in just two months.

Fortschrittliche Materialien für hochpräzise, hochreine Anwendungen

Ununterbrochene Produktionsläufe

Insgesamt sicherere Teile

Weniger Abfall

Unsere jüngsten Kooperationen definieren neu, was es bedeutet, ein technischer Partner zu sein, und bringen wirklich ehrgeizige Ideen zum Leben.

Zukunftssichere Waferproduktion mit einem fortschrittlichen neuen Polyamid-Imid

Entwicklung neuer Materialien für Hightech- und Highspec-Anwendungen

In Zusammenarbeit mit dem Erstausrüster haben wir ein bereits in der Entwicklung befindliches Material verfeinert, um seine Spezifikationen zu erfüllen, während wir seine Leistung in realen Anwendungen aktiv getestet haben. Unser verbessertes Polyamid-Imid bietet einen länger anhaltenden Schutz gegen Erosion durch Sauerstoffreinigung als typische Polyimide (PI).

Möchten Sie mehr über Halbleiter und Elektronik erfahren?

Weitere Informationen über Mitsubishi Materials Sales

Novaplas Precision hat sich auf den Vertrieb von hochwertigen technischen Kunststoffen von Mitsubishi spezialisiert und bietet eine Reihe von Materialien für verschiedene industrielle Anwendungen an. Wir bieten Materialien von höchster Qualität, ohne Porosität und mit kurzen Lieferzeiten, um Ihre Produktionsanforderungen zu erfüllen.Wenn Sie Fragen zu Mitsubishi-Werkstoffen haben oder eine Bestellung aufgeben möchten, zögern Sie bitte nicht, uns zu kontaktieren. Wir sind gerne bereit, Sie bei Ihren Materialanforderungen zu unterstützen und eine rechtzeitige Lieferung zu gewährleisten.

Glücklich: Generaldirektor

+86 151 9032 3888 (WhatsApp verfügbar)

lucky@novaplas.cn