Highlights

KyronTEX™ case study summary

We are working with Boeing to help them process and evaluate KyronTEX™ thermoplastic composites for sidewall panels on their aircraft.

MCAM introduced Boeing to our new recycled carbon fiber composite KyronTEX™ and is advising them on process technologies to utilize our product.

Industry: Aerospace Industry

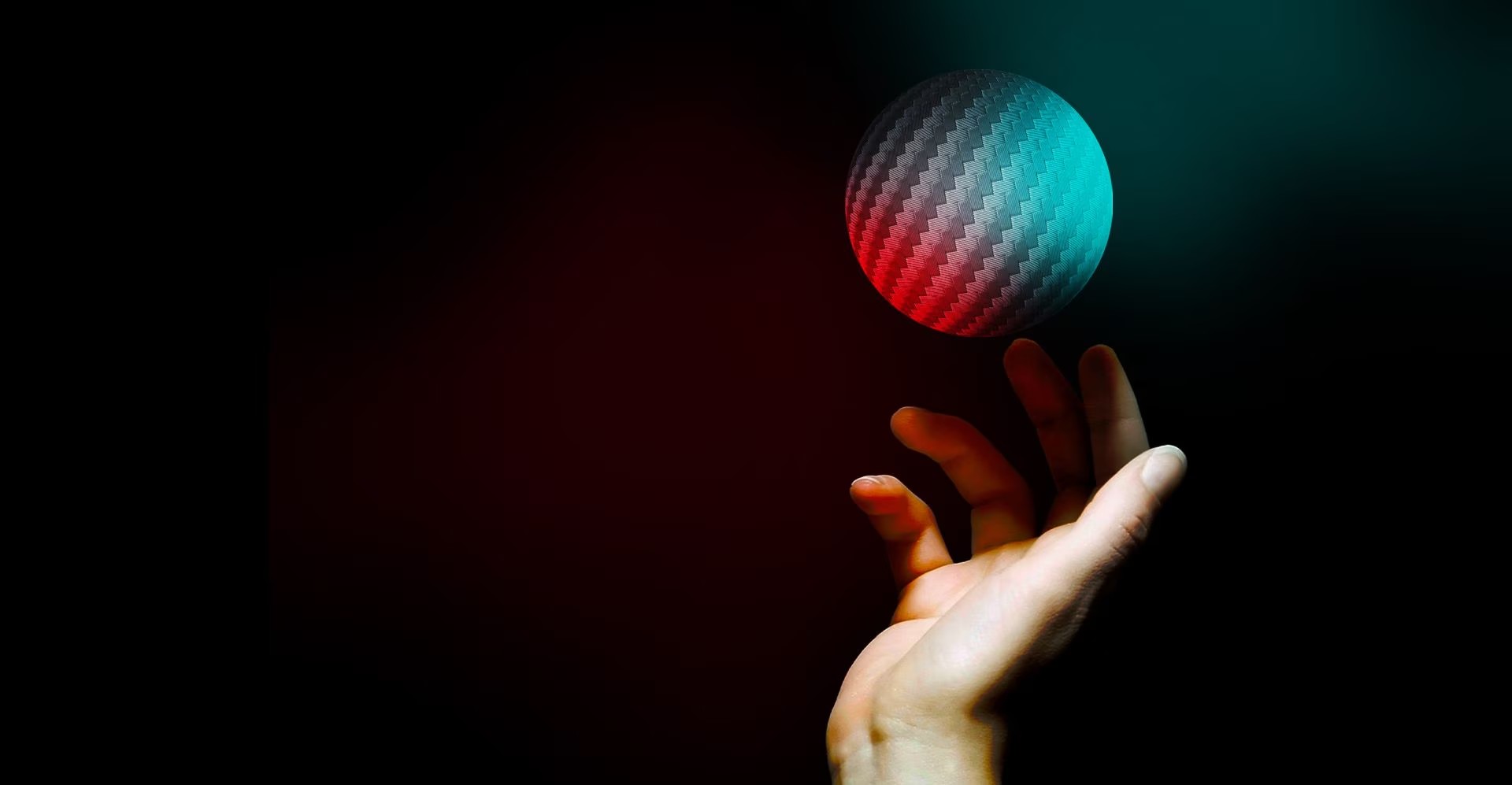

Solution:A carbon fiber composite that reduces carbon footprint by using recycled carbon fibers rather than virgin carbon fibers.

Products: KyronTEX™

Results:Cost-effective, more streamlined processes using sustainable materials while meeting Boeing’s quality standards and aerospace industry specifications.

Challenge

Meeting environmental targets in Aerospace with KyronTEX™

Driven by consumer demand and industry standards, Boeing is committed to reducing the amount of aerospace waste going to landfills. One way they are working towards this goal is by replacing traditional materials with more sustainable, recycled materials without compromising on performance.

Boeing is looking to improve resource efficiency in the production of the interior panels of their aircraft by transitioning from a traditional thermoset process to one utilizing thermoplastics.

To do so cost-effectively and without compromising on performance, they need knowledge that extends beyond the traditional material options and the process technology used to manufacture them. The innovative KyronTEX™ thermoplastic composite technology platform may enable Boeing to achieve these objectives.

Solution

More innovative materials, more sustainable processes

Mitsubishi Chemical Advanced Materials introduced Boeing to our recycled carbon fiber material – KyronTEX™ – an innovative thermoplastic composite technology platform that requires less resource-intensive manufacturing to achieve the desired part performance. We worked with them to fabricate prototype cabin sidewall panels from this material.

Between recycled sourcing and fabrication efficiencies, the use of KyronTEX™ composite in cabin sidewall panels may contribute to a significant reduction in emissions at every stage of the part’s lifecycle – from raw material through manufacturing.

We have provided Boeing with end-to-end support for this case study – working with them on our processing equipment and sharing our technical knowledge around fabricating thermoplastic composite parts to facilitate their efforts in reducing waste and costs.

If successful, utilization of our recycled KyronTEX™ composite would enable Boeing to stay at the forefront of sustainable practices within the Aerospace Industry.

Results

Driving sustainability through innovation

Thanks to our simplified composite technology processes and innovative recycled KyronTEX™ material, we are helping Boeing satisfy both consumer demands and industry pressure to reduce the amount of aerospace waste going to landfills associated with their aircrafts.

Improved processing systems

Maintained performance

Reduced carbon footprint

Our latest collaborations are re-imagining what it means to be an engineering partner while bringing truly ambitious ideas to life.

Rewriting the manufacturing process with KyronTEX™

Our composites experts shared KyronTEX™, with our partner Oribi and together we helped realign their production processes and create a more cost-effective, better-quality motorcycle helmet.

Rewrite what’s possible with carbon fiber composites

We partner with OEMs and engineers, giving them the tools they need to successfully replace traditional materials with cost-effective, future-ready carbon fiber composite materials.

More Information on Mitsubishi Materials Sales

At Novaplas Precision, we specialize in the sales of high-quality Mitsubishi engineering plastics, offering a range of materials suitable for various industrial applications. We provide materials with superior quality, no porosity, and fast delivery times to meet your production needs.If you have any questions about Mitsubishi materials or would like to place an order, please don’t hesitate to contact us. We are here to assist you with your material requirements and ensure timely delivery.

Lucky: General Manager

+86 151 9032 3888 (WhatsApp available)

lucky@novaplas.cn